Copymaster 3D 300 - The Filament role call. V4.0 Final

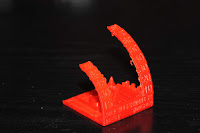

Intro Here are my general findings about various filaments that I have used in the Copymaster 3D 300. There are plenty of reviews out there, some of them are quite good, this is an unbiased view on each of the ones I have used and quite possibly more of a reminder for me than anything else. This was a regularly updated blog entry which was last updated 25/01/2021 Settings have been added for reference to see what I had to do to make them work. Generally it is not a lot but you will see variations in quality control showing up through these figures. Images are there for examples. I haven't done benchmark tests between the different filaments as I am always modifying my machines and how I print so it wouldn't be fare. I'll leave that to Youtube influencers and the like. As this page was getting a bit confusing, I have now limited this one to filaments used on the Copymaster 3D 300 sliced in Cura. Head here for the Prusa i3 Mk3s based reviews. PLA 3D Jake Da