Time to level with you, with a BL touch - Copymaster3D 300

Intro

After a lot of time faffing to get the first layer dialed in I now decided to buy a BL touch.I half hoped it would be able to compensate for the less than flat bed on the Copymaster as well as save me from endlessly resetting up the bed levelling.

The BLtouch is a contact based auto bed leveling system which will work with all surface types unlike capacitive. It's downside is it is mechanical so has all of the problems that that comes with but it is very simple which does reduce the things that can go wrong with it a bit.

You can get a copy of the BLtouck V3 for just over a tenner if you are into gambling or the genuine real deal will set you back aroun £40 if you want to DIY this.

Copymaster3D do a kit and I would expect that Technology outlet will have them ready soon. This is currently £49.94 (inc VAT) which is barely more than the BLtouch on its own and comes with pre-made wires, a mounting bracket, a wealth of software info and instructions. Not bad at all, well done Copymaster3d!

Install

The instructions are pretty decent, coming in a Google drive file (which has a mobile phone qi code link but you want to access the files by your computer which is a bit odd) is rammed full of good stuff and really did make this a breeze. I took the time to run the wiring through the snake skin and ties to tidy everything up so it didn't look a complete mess.

I took the time to run the wiring through the snake skin and ties to tidy everything up so it didn't look a complete mess.Wiring in the main board was easy enough with the printer on its side I had quick access. Power was taken from a spare socket and the control went in where the Z axis lower limit switch previously was plugged in.

With everything put back together I dumbly powered up and hit the home button, driving the printing head into the bed. Whoopsy. A quick power cycle and an apology later and I went back to the instructions that I clearly wasn't following very well.

I now flashed new firmware which enabled the BL touch which seems to have taken everything else back to the older firmware version which is a shame.

Upon powering on the BLtouch lit up red and everything else seemed to be doing what it was supposed to. Hitting home now would bounce the printing head to the centre of the printing bed where it would take a touch test before settling about 15mm from the bed.

Z axis calibration

There were basic instructions on how to bed level using the printer controls but I ended up following the Z axis calibration setup with a Bltouch guide from 3DMN on youtube.This uses Printrun for altering the firmware which is easy to use and the video uses easily understood language to get you through it. There is no point in me gong through the process here as the video does such a good job. Basically it involves some M and G cove inputs and measuring a clearance with a piece of paper much like you would normally.

One problem I had the first time round was that: something after the M581 Z**.** part where you actually set the Z offset didn't work properly and my Z offset remained at 0. Thankfully as I had read the manufacturers setup guide first, I just input it via the printers controls under "Control>Movement>Z Offset" where I spun the knob till it read the -2.60mm offset I had found previously. Then once set I went back a couple of steps and down the menu to find "Control>Save Settings" which gave out a conformation beep.

I followed this with a first layer test print but I was a bit disappointed to see the nozzle sat about 1mm off the bed squeezing filament everywhere (although now I had the wipe setup I at least had a prewarning). I probably could have fixed this on the fly but it would have been messy dragging plastic all over the bed so I stopped and restarted, dropping the head through increments till I got something to stick. This wasn't the smooth setup I was hoping for and the long wait for the thing to warm up and self level got very tedious. I will see if I can get it to move faster between tests and it really doesn't need to move that slowly here. Also I don't see why it cant stat as soon as the bed it hot. that way the hot end could be warming during the level checks. I guess its not much of a saving when compared to a big build though.

I eventually put in over 1mm extra offset ending up around -3.75mm. to get a good first layer test completed.

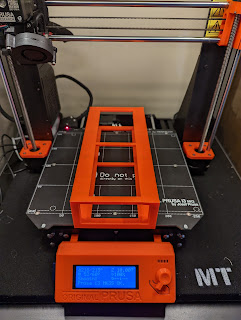

I eventually put in over 1mm extra offset ending up around -3.75mm. to get a good first layer test completed. I wanted to print something that would test the whole area of the bed and decided to print out all of the parts to make a camera gimble. I ended up building all of the parts as 1 I didn't read the readme file and 2 in hindsight it was interesting to try the all in one print.

I wanted to print something that would test the whole area of the bed and decided to print out all of the parts to make a camera gimble. I ended up building all of the parts as 1 I didn't read the readme file and 2 in hindsight it was interesting to try the all in one print.The quality varied across the plate with some parts coming out near perfect whilst others has some Z axis separation as well as bed separation still!

I have already started to notice small variances with the BLtouch base height. I have gradually pulled the deck height back up a small amount as the wipe could no longer extrude due to filament slip and the first layer was buried deep into the bed. It seemed like I had a fine line between bed adhesion and being far too low.

I would need to work a bit more at setting this printer up.

Comments

Post a Comment