Sticky bedding V1.0 - Copymaster3D

Intro

A sticky bed is normally not a good thing, your "bargain" hotel might not be as great as you hoped. If the bed in question is gripping your 3D printed piece however, you might be a touch more appreciative and less grossed out.

Flat is better

Level the bed

First you need to get the bed level or nothing will stick no matter how good your surface is.

I will add a bed levelling blog entry in the future but there are plenty of blogs and videos out there that will show you how to do this on any printer. I found a Bltouch upgrade took the work out of this a bit but brings its own problems.

Don't forget to get fundamentals right too. You can spend an age levelling your bed but if your Z axis is out of whack, you are going to hit problems as things get taller.

Don't forget to get fundamentals right too. You can spend an age levelling your bed but if your Z axis is out of whack, you are going to hit problems as things get taller.

Flat surface

Your printing surface itself may also not be flat. This is a problem I had where the bed was slightly U shaped. I fixed this by shimming the middle of the bed out with masking tape then placing the printing surface on top of it. Not ideal but cheaper than replacing the heated bed or machining.

Your printing surface itself may also not be flat. This is a problem I had where the bed was slightly U shaped. I fixed this by shimming the middle of the bed out with masking tape then placing the printing surface on top of it. Not ideal but cheaper than replacing the heated bed or machining.I will talk in more detail on this in another specific blog entry.

heat

A heated bed helps plastics better adhered to it. PLA doesn't need a heated bed but it certainly helps. Also, if your printer will let you, try setting the slicer to turn the parts fan on (or up if it is a shared fan) after the first layer. If you can get that first layer down, the rest should have itself.

Surface choices

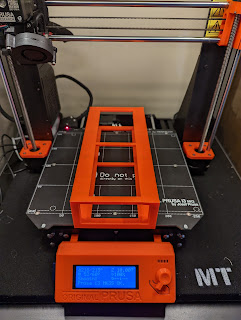

You will most likely have the choice made for you initially. The bed that comes with your printer, in theory, is the optimum one for your printer set up. Or the most cost effective at least. Glass is still the proffered printer bed surface as it is generally flat and smooth although it will need some help and some materials like PETG will tear chunks out of it if you aren't careful about preparation.

You will most likely have the choice made for you initially. The bed that comes with your printer, in theory, is the optimum one for your printer set up. Or the most cost effective at least. Glass is still the proffered printer bed surface as it is generally flat and smooth although it will need some help and some materials like PETG will tear chunks out of it if you aren't careful about preparation.Magnetic removable surfaces help remove your parts after they are printed but are easily damaged by your hot end if you aren't careful about where you let the head linger or it digs in.

There are other surfaces out there such as metals and even glass fibre but it will be down to your personal choice, or the choice of your printers manufacturer, as to what you use.

There are other surfaces out there such as metals and even glass fibre but it will be down to your personal choice, or the choice of your printers manufacturer, as to what you use.I am currently using glass and have had the most success with it. I may return to the removable magnetic bed in the future to see if I can get it to work properly as it is a nice feature.

There will no doubt be a blog about this one too.

A little help

There are bespoke products out there that you can buy to help with bed adhesion as well as tried and tested favourites: Masking tape, glue stick and hair spray.

Here are the products I have used and what my experience was:

Fish hair spray

Fish hair spray

it was an improvement over nothing with my fist ever print coming out with the help of this product. I only used it as I had some kicking about when the printer first arrived and nothing would stick on my bed.

As you can see, I have some lifting on this small PLA print (my basic G code printer settings weren't even setup properly here with no wipe hence the broken skirt) and as time war on I soon lost patience with endlessly failed first layers.I think the cause of this progressive failure rate is because this premium hair spray probably contains oils which built up over time lubricating the surface which you don't want. I wouldn't recommend it anyway.

Wella strong hold hair spray

After cleaning the surface I tried this out and it did nothing. The one thing it is good for its to add a slightly roughened surface to glass to help glue stick do a better job. Another one I wouldn't recommend.

Tack glue stick

So far this is my go to for bed adhesion. I have used it on the magnetic bed and glass with good results. I apply a thin layer in the X then Y direction on top of one another for the area I intend to print.

I find that after 10-15 prints, the surface gets a bit messy but rather than removing the glue completely, I go over it with a damp cloth. Without changing the part of the cloth I use, I work round the plate till all of the glue is liquid again where it will ready in a thin uniform film.

One nice thing about the Tack branded glue stick is that it goes on blue and dries clear so you can see where you have applied the stick easily. It is a premium glue stick though so I will be trying others in the future.

There are other ways out there. I have heard good things about Salisbury's basic hair spray which I will be trying and no doubt some cheaper glue sticks will be found too.

I will update this section of this blog entry whenever I try a new product so do watch this space.

One nice thing about the Tack branded glue stick is that it goes on blue and dries clear so you can see where you have applied the stick easily. It is a premium glue stick though so I will be trying others in the future.

There are other ways out there. I have heard good things about Salisbury's basic hair spray which I will be trying and no doubt some cheaper glue sticks will be found too.

I will update this section of this blog entry whenever I try a new product so do watch this space.

Comments

Post a Comment