Organic supports 0.0.1

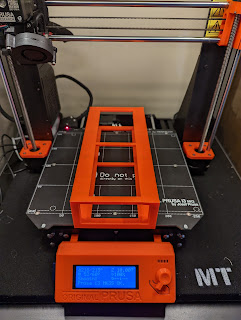

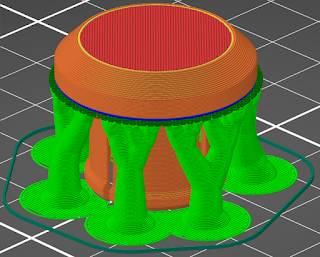

fig1.1 PrusaSlicer 2.6.0 Beta Intro Organic supports are new for Prusa Slicer 2.6.0 Beta and are getting quite a lot of love online so I thought I'd give them a go. fig1.3 First off a copy of Prusa Slicer 2.6.0 Beta was downloaded and dumped in a folder meaning that every time I want to use it I have to go folder diving, thinking I really should make a shortcut for it (which we all know I will never do). I dialled in some custom support settings courtesy of a Reddit blog showing off some easily removed organic supports. Sadly I can't find the original post now but I did take a screen shot on my phone which you can see in fig1.2. So far, so simple. I am currently printing some motorcycle stem caps for HPE which I was currently printing with traditional supports. I usually avoid using supports but this model needed them to print correctly. I was also using Concentric infill and a 1.0 layer height for aesthetic reasons. The results were a bit more miss than hit however. fig1....