Prusa i3 Mk3s - The Filament Roll call V1.1.1

Intro

Here are my general findings about various filaments that I have used in the Prusa i3 Mk3s. There are plenty of reviews out there, some of them are quite good, this is an unbiased view on each of the ones I have used and quite possibly more of a reminder for me than anything else.

I use PrusaSlicer for all of my slicing needs when printing with the Prusa printer. I tend to use the built in profiles which are generally bob on with the option of titivating things in the Tuning Menu.

Settings have been added for reference so you can add these to your own slicer. As a general rule, first layers are 5-10℃ lower temperature and no fan.

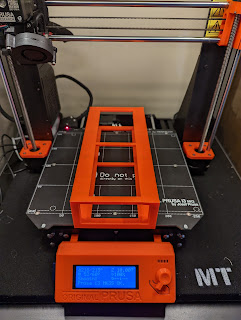

Images are there for examples. I haven't done benchmark tests between the different filaments as I am always modifying my machines and how I print so it wouldn't be fare. I'll leave that to Youtube influencers and the like.

I have separated my Prusa i3Mk3s based filament reviews and settings from the Copymaster. This is mainly to keep things tidy as it was getting messy on the old review page

Version History

This is a regularly updated blog entry which was last updated 01/03/2021.

V1.1.1 - Added quick note on Fiberlogy and picture

V1.1.0 - Added packaging details as this is useful to know if you don't keep those resalable bags and is an indicator of quality sometimes.

-Added 3D Jake and Fibrelogy PETg.

-Updated colorfabb quick notes.

-Updated Technology outlets quick note.

V1.0.0 - Copied across from old Copymaster based roll call

PLA

I generally only use PLA for test prints and occasionally ornaments. I tend to use the base settings in PrusaSlicer and keep the enclosure doors open.

3D Jake

Weight of new roll: 1.254kgDiameter as measured: 1.72mmFilament Profile: - Prusa PETgTune: - +3%.Flow rate:103%

Nozzle temp: 215℃

Bed Temp: 60℃

Fan: 100% (Disabled for first layer)

Speed: 50mm/s

Filament Profile: - Prusa PETg

Tune: - +3%.

Flow rate:103%Nozzle temp: 215℃

Bed Temp: 60℃

Fan: 100% (Disabled for first layer)

Speed: 50mm/s

Quick note: It measures up a bit skinny, bobbin is a bit flimsy and filament is spooled untidily. That aside it prints really well with a nice finish, surprisingly good bridging and not much mess. Standard profile does show slight under extrusion.

PET-g

AS with PLA; I tend to use the base settings in PrusaSlicer and will test and adjust if I hit an issue or something is dimension critical.

3D Jake

Date: 2021

Weight of new roll: - 1.250kgPackaging: - Box, plastic wrap & desiccant.

Diameter as measured: -1.74mm

Filament Profile: - Prusa PETg

Tune:

Flow rate:95%

Nozzle temp:250℃ (first layer 240℃)

Bed Temp: - 90℃ (first layer 85℃)

Speed:45mm/s

Quick note: The tiny amount I have used so far has printed as well as any other. Characteristic PET stringing but otherwise a nice smooth finish. Prints great out of the box but a lack of resealable bag will mean I will be cooking this one a lot more than others before I use it.

ColourFabb economy

Weight of new 2.2kg roll: - 2865g

Packaging: - Box, plastic wrap & desiccant.

Diameter as measured: -1.76mm

Diameter as measured: -1.76mm

Filament Profile: - Prusa PETg

Tune:

Flow rate:- 95%

Nozzle temp: - 250℃ (first layer 240℃)

Flow rate:- 95%

Nozzle temp: - 250℃ (first layer 240℃)

Bed Temp: - 90℃ (first layer 85℃)

Fan: - 30% (Disabled for first layer)

Speed: - 45mm/s

Quick note: I have started using it whilst printing an enclosure frame with the huge roll on a surface stand. This has suffered a number of problems:

Fan: - 30% (Disabled for first layer)

Speed: - 45mm/s

Quick note: I have started using it whilst printing an enclosure frame with the huge roll on a surface stand. This has suffered a number of problems:

|

| 0.4 nozzle pre enclosure |

Otherwise; the final product remains strong with the colour ever so slightly on the grey side of black. This large roll has needed drying fairly frequently as its size and lack of reusable packaging has meant it is left in open atmosphere quite often. I have found decanting this roll down to smaller rolls makes it more manageable for use and storage. Otherwise this is best used when you plan to use the whole roll on batch/large prints over a few days.

Fiberlogy

Date: 2021

Packaging: - Box, resalable bag and desiccant.

Diameter as measured: -1.72mm

Diameter as measured: -1.72mm

Filament Profile: - Prusa PETg

Tune:

Flow rate:- 95%Nozzle temp: - 250℃ (first layer 240℃)

Bed Temp: - 90℃ (first layer 85℃)

Fan: - 30% (Disabled for first layer)Speed: - 45mm/s

Quick note: Prints as well as any other using prusas base PETg settings. Finish is nice with little to no stringing for this multi part print. Spool is pretty funky looking, forgot to weigh it at the beginning though didn't I.

Filament PM

Date: 2020

Weight of new roll: -

Packaging: - Box, resalable bag & desiccant.

Diameter as measured: -1.72mm

Diameter as measured: -1.72mm

Filament Profile: - Prusa PETg

Tune:

Flow rate:- 95%Nozzle temp: - 250℃ (first layer 240℃)

Bed Temp: - 90℃ (first layer 85℃)

Fan: - 30% (Disabled for first layer)Speed: - 45mm/s

Quick note: Initially I had issues with bed adhesion running a generic PET profile and couldn't get a print to start on the Prusa. Raising the temps to the Prusa PETg profile fixed this and with a ball park extrusion, appears to have produced a good test piece.

All bridging tests were faultless and dimensionally it is pretty bob on. Without getting too hung up on the test piece: I have found this filament to work as well as Prusa's own PETg which I have set as a bit of a benchmark.

Whether printing in the orange or clear, this stuff gives good strong results with a pleasing surface finish. Occasional zits and dropped burnt bits are more than likely more reflective of printer condition and setup than the filament and as you can see on the left, I can confidently print large batches of easily damaged parts without issue.

Prusa

Packaging: - Box, resalable bag & desiccant.

Diameter as measured: -1.74mm

Filament Profile: - Prusa PETg

Tune:

Flow rate:95%

Nozzle temp:250℃ (first layer 240℃)

Bed Temp: - 90℃ (first layer 85℃)

Speed:45mm/s

Quick note:This is a premium filament and as you might expect, it prints very well indeed. The price is a bit more than some of the examples shown but for the sake of a tenner more a roll, it makes a big difference. I very rarely have issues when printing with this stuff making it my first choice to use when price isn't my top priority.

As can be seen in the examples shown, the finish is very good. Another nice thing about using this filament is how supports are easier to remove as is removal from the flexible bed. I rarely mess with printer setting, allowing Prusa slicer do all of the leg work. the chart on the box gives filament diameter for the whole roll making measurement un- necessary. I have got through a few rolls now in a variety of colours.

Prusa PPE

Weight of new roll: - 1.214kg

Packaging: - Box, resalable bag & desiccant.

Diameter as measured: -1.72mm

Filament Profile: - Prusa PETg

Tune:+5%

Flow rate:-100%

Nozzle temp: - 250℃ (first layer 240℃)

Bed Temp: - 90℃ (first layer 85℃)

Speed: 45mm/s

Quick note: Prints faultlessly on the Prusa once flow setting were dialled in. I didn't feel the need to go over 100% flow, a slight under extrusion helps separate the visors anyway. Finish is just as good as the regular filament.

SUNLU

Weight of new roll: -

Packaging: - Box, resalable bag & desiccant.

Diameter as measured: 1.72mm

Diameter as measured: 1.72mm

Filament Profile: - Prusa PETg

Tune:

Flow rate:95%Nozzle temp: 250℃ (first layer 240℃)

Bed Temp: - 90℃ (first layer 85℃)

Fan:30% (Disabled for first layer)Quick note: This filament has been a bit of a rollercoaster. At first it was my realisation that it wouldn't work at all with the Copymaster 3D 300, then I was happy to see it working well on the Prusa. A while later I tried to print a large solid object and it just repeatedly failed to finish the print due to collisions caused by globs on the surface. I never managed to get a tidy print even after cooking the filament in the oven to bake out any moisture and set it aside for test prints only. A good while later, running low on black PETg, I used this roll for enclosure frame parts and it printed fine. No issues whatsoever and a perfect outside finish. Very strange.

Technology Outlet

Date: 01/2021

Packaging: - clingfilm only.

Weight of new 1kg roll: -

Packaging: - Box, plastic wrap & desiccant.

Diameter as measured: -1.76mm

Diameter as measured: -1.76mm

Filament Profile: - Prusa PETg

Tune:

Flow rate:- 95%

Nozzle temp: - 250℃ (first layer 240℃)

Flow rate:- 95%

Nozzle temp: - 250℃ (first layer 240℃)

Bed Temp: - 90℃ (first layer 85℃)

Fan: - 30% (Disabled for first layer)

Speed: - 45mm/s

Quick note: I had initial issues with the clingfilm used to seal the roll sticking to the filament causing contamination. Technology outlet offered a partial refund for this issue.

Fan: - 30% (Disabled for first layer)

Speed: - 45mm/s

|

| Contaminated filament |

Quick note: I had initial issues with the clingfilm used to seal the roll sticking to the filament causing contamination. Technology outlet offered a partial refund for this issue.

The larger 2kg roll will not fit on a standard spool holder so a surface holder is needed. The filament itself prints just as well as their other products and the price is very good when there is a sale on.

Comments

Post a Comment